The Modular Bioreactor platform consists of different types of bioreactors that can be used in a sequential and parallel set-up. This platform allows the investigation of sustainable solutions for environmental challenges. Amongst others, these include generation of sustainable energy, recovery of resources from complex waste streams, and removal of pollutants. In this case study, we illustrate the latter example with the use of constructed wetlands.

By The Modular Bioreactor Platform / September 7, 2021

KEY MESSAGES

- Micropollutants, which are present in the water environment, form a potential danger to the environment and human health.

- Constructed wetlands form a cost-effective and sutainable way to remove pollutants from water streams.

- To illustrate the use of our Modular Bioreactor Platform, this case study describes the performance of different combinations of constructed wetlands in a modular way.

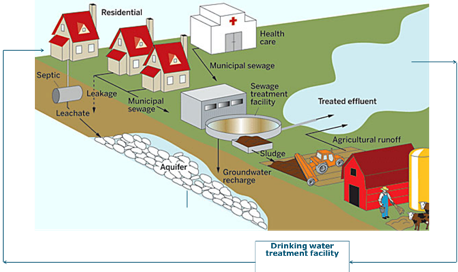

In the last decades, micropollutants have been observed at low concentrations (ng/L to µg/L) in water streams. As they end up in important water resources, such as water for production of drinking water, they form a potential danger to the environment and human health. Therefore, technologies need to be designed to remove them from the water and to understand the fate and transformation of these compounds. To this end, combinations of microbial, chemical and physical processes in novel reactors hold promise. Finally, these systems need to be designed, developed and tested.

Constructed wetlands

Constructed wetlands (CWs) are designed to mimic natural processes that use plants, microbes and soil to treat wastewater in a controlled environment. In these CWs, major processes to remove pollutants concern the following:

- aerobic and anaerobic biodegradation

- photodegradation

- plant uptake and transformation by plants, and

- sorption to the sediment

Especially aerobic and anaerobic biodegradation by unknown microbial communities, forms a key mechanism to remove compounds in CWs. These communities are attached to the sediment and plants, as well as present in biofilms. In general, the costs of CWs are low compared to regular wastewater treatment plants. Therefore, the application of CWs as a tertiary treatment step to remove low concentrations of micropollutants from wastewater streams has been studied more and more.

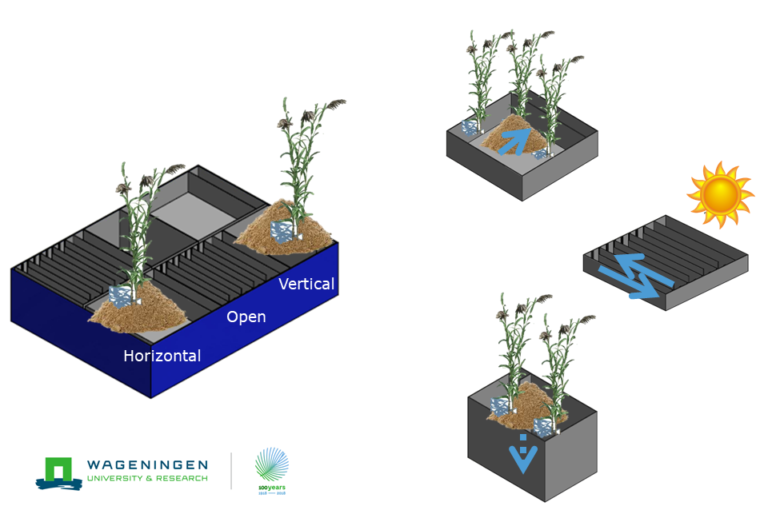

Case study: Pilot-scale hybrid constructed wetlands

In this case study, we installed hybrid-constructed wetlands with three water flow types in different combinations, which are

- vertical subsurface flow CW

- horizontal subsurface flow CW, and

- surface flow CW

In total, six different hybrid-constructed CWs were installed, which allowed us to test all the possible sequences with the three CW types in a modular way. The CWs consisted of sand and gravel, and were planted with Phragmites australis. Next, they were fed with a synthetic medium at a flow rate of 140 L/d, resulting in an hydraulic retention time of 7.5 days. In summary, we studied the removal of phosphate, benzoic acid, and benzotriazole in these CWs.

Performance of the contructed wetlands in summer

We ran the CWs for a full year, which allowed us to investigate the removal efficiency of the CWs over time and through different seasons. This way, we found that benzoic acid and nitrate were removed by biodegradation, while phosphate was removed by adsorption and plant uptake. Additionally, benzotriazole was removed by adsorption and biodegradation, and its removal efficiency steadily increased from 40% to 100%. We hypothesized that this was due to adaptation of the microbes towards biodegrading benzotriazole. Further, in summer, the removal efficiency of compounds removed by microbial processes was higher than in winter, likely as a result of a higher microbial activity.

Performance in autumn

Subsequently, in autumn, we removed the plants from the CWs. The resulting decrease in temperature lead to less input of oxygen and nutrients for microbial processes. As a result, we oberved a lower removal of compounds that rely on microbial degradation (i.e. benzoic acid, nitrate and benzotriazole) in the horizontal flow CW. In contrast, the vertical flow CW performed similarly as in summer.

Performance in winter

Next, in winter, the surface flow CW was frozen for two weeks and no operation of the hybrid-CWs was possible. When not frozen, the low temperatures and absence of plants resulted in a lower microbial activity especially in the horizontal flow CWs. Nevertheless, the vertical flow CWs performed better. However, the overall performance of the CWs depended on the figuration (i.e. the used sequences) tested.

Research of the Modular Bioreactor Platform

In general, CWs are often seen as “black boxes”, in which removal efficiency is determined by comparing influent and effluent concentrations. When biodegradation is an important mechanism to remove compounds, finding the dominant microbial removal mechanisms for specific compounds in CWs, allows the prediction of removal efficiency and the formation of possible toxic products. This is crucial to design a CW for the removal of specific compounds, and identify if pre-treatment (e.g. photooxidation) or post-treatment (biological polishing) in other treatment units is needed. Furthermore, the different designs of a CW can steer specific removal processes, such as the presence of various redox conditions. All in all, the resulting flexibility in design and combinations of constructed wetlands are part of the Modular Bioreactor platform.

Interesting links

When you want to read more on the use of constructed wetlands, please read our research paper and review here:

If you want to read more about this platform, check out the platform page.